SimG Co., Ltd. has successfully delivered a standard-model forklift simulator to a university located in Gumi.

This implementation contributes to upgrading students' field-customized vocational training and safety education.

SimG recently announced the successful delivery of a basic forklift simulator to a university in the Gumi region.

Aimed at strengthening students' job competencies, this project was launched to enhance limited practical training environments and reinforce safety education.

Although forklifts are widely used in logistics, manufacturing, and construction, opportunities

for hands-on practice are limited and beginner operators face a high risk of safety incidents.

The simulator was introduced to provide ample virtual training prior to real equipment operation and field deployment.

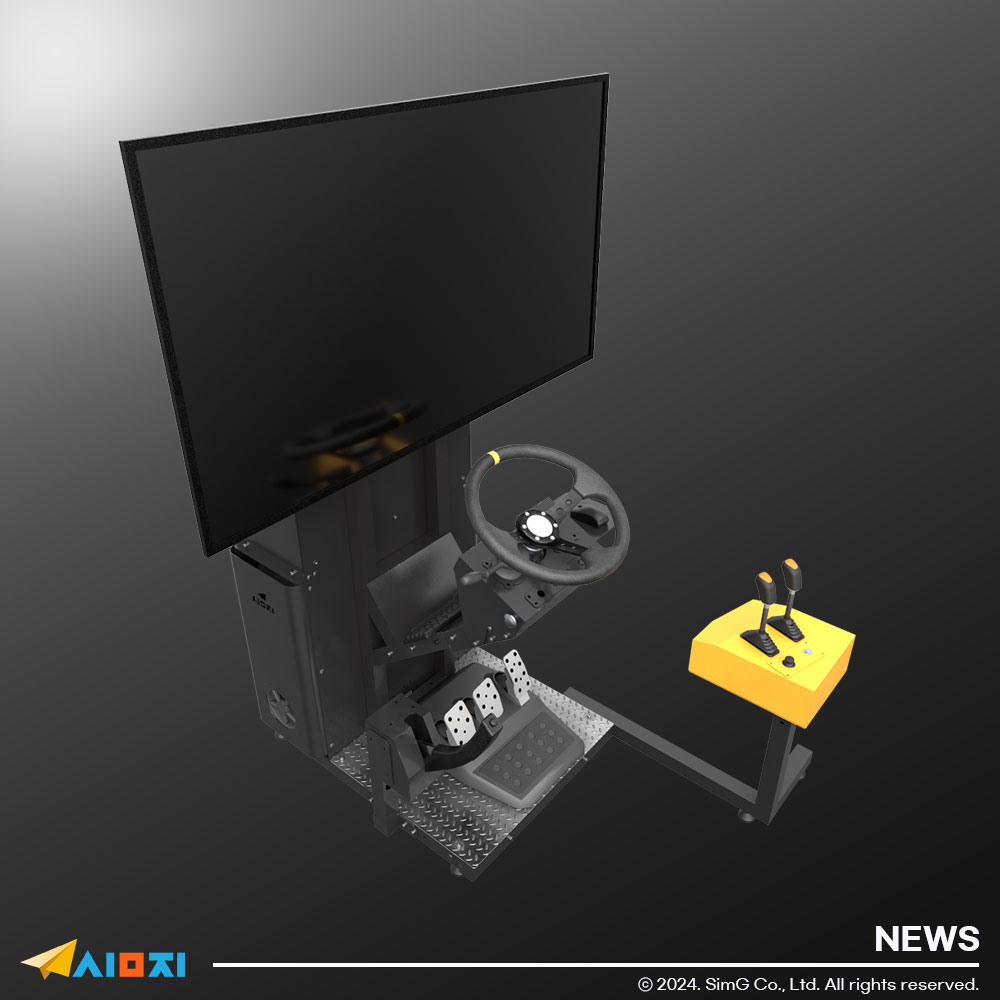

Despite being a basic model, the delivered forklift simulator offers high immersion by incorporating hardware closely resembling actual equipment

(e.g., control levers, pedals, seat). Students can learn the fundamental principles of forklift operation through a virtual interface,

including license test practice mode and simulated work environments. Additionally, it supports diverse scenario-based training, preparing learners for real-life industrial situations.

Thus, the simulator ensures safety during training while enabling repeated practice in preparation for real equipment use.

The university’s adoption of this equipment represents more than just the supply of educational tools—it reinforces the foundation for nurturing talent linked to regional industry.

Through repetitive practice, students gain practical capabilities that allow for immediate deployment in industrial settings upon graduation.

This is expected to cultivate field-ready professionals demanded by local enterprises and contribute to raising overall industrial safety standards.

Related Links